Submittals in construction are an integral part of the pre-building process. Architects, designers, and engineers create building plans that include every detail of the project. From large-scale needs down to the smallest component, they’ve considered every spec and code requirement.

Between the design phase and the build phase of a project, though, there is plenty of room for error. General contractors are responsible for the overall success of a structure, ensuring that the design is executed to the expected parameters. Each subcontractor is accountable for their piece of the process, and that includes gathering information before beginning work.

When the design is handed off to the builder, they’re responsible for doing the necessary research on the products they intend to use for the project. This includes everything in the build environment, from windows and doors to fasteners. All of their research ends up back with the design team for approval.

Large projects often have hundreds of pages of paperwork that capture products and processes around the build. Organization is key, and technology is an essential channel through which the builders and designers communicate.

Gathering necessary information for submittal paperwork can take contractors a significant amount of time. Especially in an industry that doesn’t always embrace new technology, specs may live in outdated filing systems or not be readily available. Then, reformatting product information into that required by the design team is another process altogether.

Submitting improperly formatted or incomplete information can send contractors back through the whole process. Getting a Rejected stamp means meetings with the team to discover the issues, regathering details, and hopefully passing the second time.

When builders make substitutions to elements like fasteners, it’s often more about availability than anything else. Going back to the drawing board on a fast-moving project can mean delays and further setbacks. Contractors who can’t source fasteners or other products can be left high and dry.

In most cases, submittals must be approved, or at least signed off on, by the design team before the beginning of construction. On the Young Architect Podcast, they recommend contractors aim for 80% completion before breaking ground, which is a good target. As noted, contractors might submit hundreds of pages to the design team, and getting them in early can keep your project on track.

No matter your trade, the design team must approve your submittals before beginning construction. This serves to protect both the team and subcontractors by ensuring builders use the correct product in every instance. Unclear specs from the design team can lead to costly mistakes down the road, so details are essential.

Submittals allow contractors to share exactly which products they’ll use to complete their part of the project. If they can’t find the exact parts specified, in some cases, a different product will suffice. Submitting their choice to the design team ensures that whatever they plan to use still meets the performance specs needed for the project.

Once submitted, there are several possible responses:

In cases where amendments are necessary, they must be made before any construction begins to ensure compliance.

Communicating technical data to the design team requires contractors to gather information on each product. Pulling together safety data, technical data, and other details can be challenging when manufacturers don’t have current information available.

The research process can be time-consuming, and time equals money. To facilitate this process, Pro-Twist launched two tools on its new website.

Each of these applications streamlines the process for contractors, making the submittal process fast, simple, and professional.

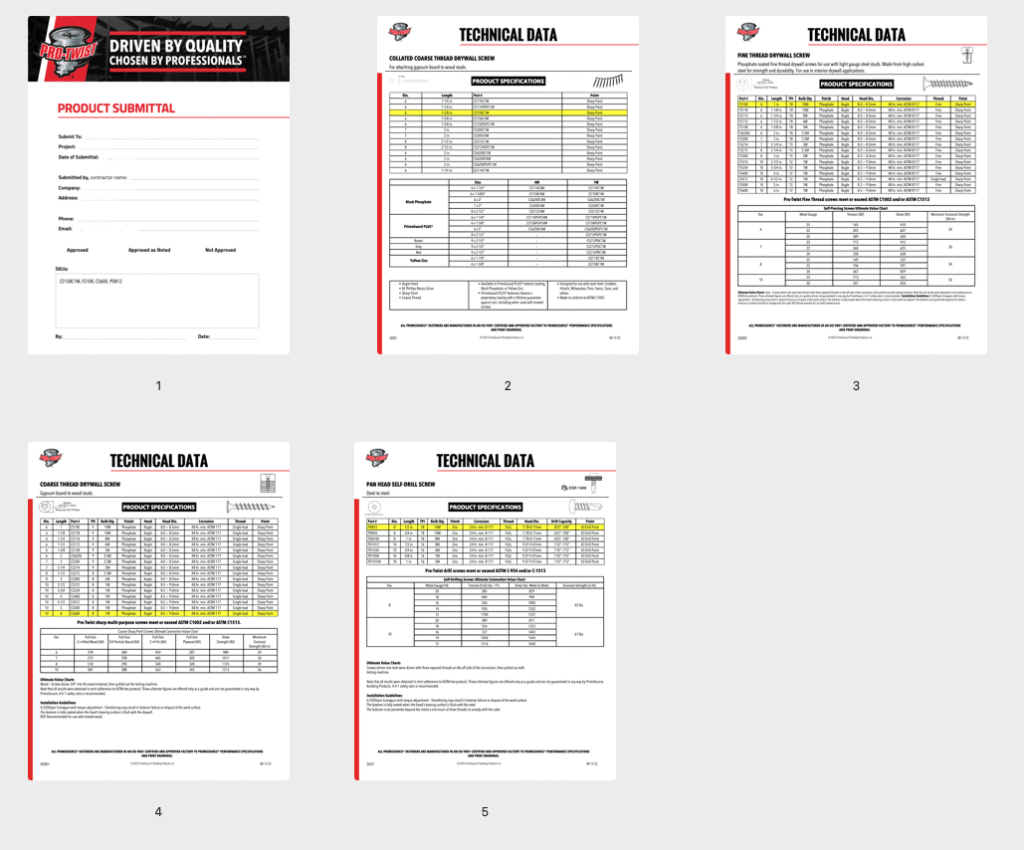

With the launch of our revamped website in 2025, Pro-Twist users now have access to a powerful tool that makes submittals simple. This free tool allows contractors to select products and have a tailored package of PDFs emailed directly to them.

To use the tool, follow these steps:

You’ll get a cover sheet with pertinent project information and technical data sheets of each fastener selected.

The output from our submittal tool is straightforward, easy to understand, and provides the design team with what they need to make decisions. Once approved, our Where to Buy tool makes it easy to purchase Pro-Twist fasteners for your project.

Using our tool to build submittals makes the process smooth and quick. Contractors who embrace newer technology will appreciate how simple it is to use. It reduces the time spent gathering information from hours to minutes, providing a standardized format for quick approvals.

Each contractor requesting a submittal gets a custom document with only the information needed. We keep our database up to date, so all of the information conforms to current standards and codes. You’ll have fewer RFIs and red flags from architects and engineers, streamlining the approval process.

We’ve also included clean and modern branding as part of the approval package. It might seem like a small detail, but building credibility with GCs as a subcontractor matters.

Fasteners may be small, but they’re a vital part of any construction project. With the Pro-Twist® submittals tool, beginning a new contract doesn’t have to involve deep research. We’ve made it simple to get in, get your information, and get approval.

Save time and avoid RFIs from your design team with our comprehensive data sheets. Just a few clicks get you precisely what you need to keep moving.

Build your first Pro-Twist submittal packet today.