If your Sound Transmission Class (STC)-rated assembly isn’t performing as expected in the field, the issue might not be related to your drywall or insulation. It could be your fasteners.

In commercial partitions, hotel corridors, and multifamily floor-ceiling assemblies, even a minor mistake, such as overdriving a screw or using the wrong length, can compromise your entire sound isolation strategy. These minor missteps create rigid connections, reduce system flexibility, and allow sound to travel more easily through the system. Understanding how fastener type affects STC-rated assemblies in commercial walls is essential for preventing these issues.

This fastener selection guide for STC-rated assemblies will explore spacing, depth, torque impact, and key considerations during the installation process.

Sound doesn’t need a wide path. It only requires a stiff one. Fasteners are a common unintended stiff path. In decoupled, STC-rated assemblies, a single screw driven into the wrong place can reconnect isolated layers and create a rigid transmission path. This is known as mechanical coupling or acoustic bridging, and it’s one of the most common ways STC ratings drop in the field.

When fasteners bridge across components meant to move independently, such as resilient channels or staggered stud walls, they transmit vibration through the system. These rigid links carry vibrations that bypass insulation, air gaps, and other sound-blocking materials. Studies have shown that incorrect fastener placement can reduce STC by 5-10 points.

What matters most is the following:

Fasteners may be small, but they can have a measurable effect on how much sound a wall or ceiling assembly blocks. Choosing the right fastener type isn’t just about structural hold. It’s about minimizing the stiffness and bridging that can carry vibration from one side of a partition to the other.

In most commercial builds, self-drilling screws are the standard because they’re fast, consistent, and eliminate the need for predrilling. However, there’s a trade-off. Self-drillers create tight, rigid connections that can increase vibration transfer in sensitive parts of an STC-rated assembly, such as resilient channels or staggered stud walls.

Sharp-point or pilot hole fasteners offer more control. With a depth-sensitive driver, they can reduce the chance of deforming thin metal components or over-clamping parts meant to flex.

When choosing between these two options, consider:

Thread design affects both grip strength and the transmission of vibration through the connection. Using the wrong thread type or overdriving it can tighten the path for unwanted sound.

Different threads offer various elements:

The head of a fastener affects how force is distributed across the material’s surface, which in turn impacts acoustic performance.

You’ll need to consider the following:

For resilient channels, screws must seat in the channels only, not through to the studs. Any “clutch-controlled” or “torque-controlled” driver setting should be specified to avoid crushing channels or board.

Fastener selection is more than just following structural specs. Every screw is a potential sound path. Choosing the right type and installing it correctly helps you keep your STC rating intact from the first screw to the last.

Even the best fastener can work against you if installed incorrectly. Spacing, depth, and torque influence whether a wall performs like the tested assembly.

More fasteners don’t equal better performance. Too many screws can stiffen the wall, allowing more vibration to pass through.

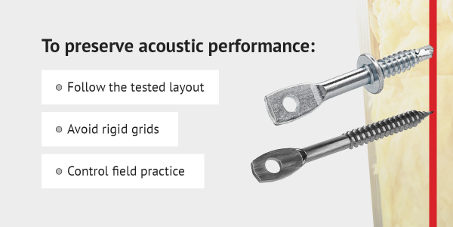

To preserve acoustic performance:

Remember that field deviations are standard, and you might require submittal review and field mock-ups.

It is important to understand whether overtightening drywall screws impacts the acoustic performance of a wall assembly. If a screw goes too deep, it can short-circuit the acoustic design. Conversely, shallow screws can loosen over time, causing rattling.

To preserve acoustic isolation:

If you’re building an STC-rated wall or ceiling, your fastening schedule is part of the tested assembly as specified in ASTM E90. Deviations from the UL design, GA detail, or other published sound assemblies will result in a new, untested assembly, voiding the rating. To preserve acoustic isolation, mirror the tested conditions.

To maintain the integrity of your acoustic performance, fastener specifications should be clearly defined, approved, and followed throughout the project. This avoids last-minute substitutions that could compromise results:

Once installation begins, it’s worth confirming that fasteners are being used and installed as planned. A simple field check can prevent rework later:

For more robust quality assurance in the final build, use field mock-ups or acoustic field testing, as specified in ASTM E336, for validation. Field testing, as per ASTM E336, will result in an NNIC or ASTC rating, which will inherently be lower than the lab-controlled STC rating. Consult your local building codes for NNIC or ASTC rating requirements, if applicable.

Precision matters when you’re focused on STC targets. From navigating tested assembly specs to helping you select the correct fasteners for your specific application, Pro-Twist ensures your acoustic performance holds up in the real world, not just on paper.

At Pro-Twist, we help you build quieter, higher-performing spaces. Our products are tested in certified assemblies, engineered to minimize acoustic bridging, and backed by a team that understands the science behind STC ratings. Whether you need support interpreting lab data, selecting fasteners, or UL-listed designs, Pro-Twist is your partner from planning to the final product.

Minor missteps can affect acoustic performance when STC ratings are at stake. This could result in a failed inspection or a complaint from a noisy tenant.

The good news is that you don’t have to solve it alone. Pro-Twist brings the technical expertise and high-quality fasteners you can rely on. They’re consistent and dependable, helping to avoid project delays and failures.