Precision fasteners engineered to exact specs are vital to the commercial and residential construction industries. Architects and engineers require components to fit together, sometimes with very little room for error. This variance, or tolerance, refers to the allowable range of variation in components from the design specifications.

All screws must fit the tolerances dictated by ISO 965-1. It addresses:

Tight tolerances are essential in industries that rely on machined elements or require precise measurements. Engineers count on threaded fasteners that meet the needs of their designs for a seamless fit.

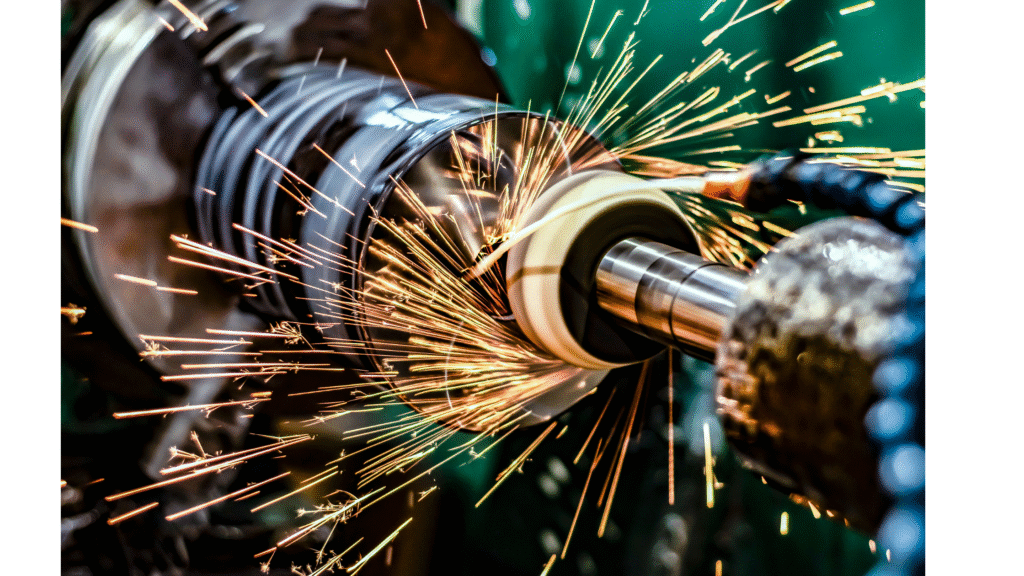

Pro-Twist recognizes the importance of tight tolerances. We focus on milling techniques that promote consistency across our fastener lines.

We’re heading to the factory floor to see precisely how Pro-Twist achieves the highest quality, every box, every screw, every time.

Crafting a precision fastener begins long before the manufacturing process. At Pro-Twist, our engineering team focuses on the design and materials used first. We use high-carbon steel for all our products to maintain sharp, well-defined points and threads.

Higher carbon content, between .7% and 1.7%, translates to what’s known as better hardenability. That means our screws resist wear and tear over time. Additionally, steel of this type has greater rigidity and resists bending under load stress.

At the end of the production process, we test fasteners twice, once at the factory and once in our labs. This ensures that each box consistently meets the needs of contractors and our exacting standards.

Precision manufacturing and rigorous testing mean that Pro-Twist customers can expect the best. We’ve engineered products for nearly every framing and fastening application, and our fasteners perform to specifications across the board.

Fasteners engineered for precision often fail to meet tolerance requirements due to manufacturing issues. Generally, screw threads are formed as blanks roll through a die. Whether it’s a rotary or stationary die, the grooves wear down over time, and the final product suffers. Rather than meeting tight tolerances, the fasteners fall to the edges of allowable tolerances.

For most wood and metal framing applications, tolerances are slightly more lenient. Pro-Twist fasteners aren’t typically used to assemble specialized machinery components that require exacting standards. Regardless, our commitment to tight tolerances has more to do with consistency than application.

Our manufacturers have die replacement protocols to maintain consistent thread measurements. After a specified number of production runs, we swap out with new die sets and test the output to ensure a precise product.

After milling, we wash our fasteners to remove excess material and dry them to remove any remaining oil. When you purchase Pro-Twist, you’ll know what you’re getting every time.

Wood-to-wood applications require a cleanly milled coarse thread that grips wood substrates evenly. Our general-purpose woodworking screws have a hard, sharp point for easy penetrations. The self-drilling T 17 point on our cabinet screws reduces or removes the need for pre-drilling and cuts through various densities of wood quickly with minimal effort.

Engineered to reduce installer fatigue and tool wear, our well-defined and consistent coarse-threaded fasteners are ideal for various construction applications.

Pro-Twist’s fastener assortment focuses on wood and steel framing, but we offer several woodworking-specific screws.

Wood-to-metal applications are typical in steel-framed structures. Securing plywood or OSB to metal framing presents some additional challenges. Dense wood can damage the fine, sharp threads necessary for metal fastening, leading to increased drive times and user and tool fatigue.

To combat this, Pro-Twist engineers included some unique features in our wood-to-metal screw assortment.

Longer points allow the fastener to pass through the wood substrate and into the metal framing member without excessive wear to the threads.

Metal-to-metal applications require sharp, self-drilling points and frequently include self-tapping as a feature. This allows the fastener to pierce the metal and create threads in the substrate for easier driving and removal if needed. A range of different point types pierce through varying gauges of steel for consistent driving.

Precision threads and complementary head types reduce stripping during driving and ensure a secure connection. Our metal-to-metal assortment is intended for use in joining sheet metal, roofing, framing, and HVAC.

Pro-Twist precision fasteners cover the full range of construction applications and include cement board screws, drywall screws, and concrete screw anchors. Threads specific to each application are precision milled for optimal performance.

Rigorous testing ensures that each thread type is cleanly milled for exceptional performance.

Architects and engineers require that the fasteners they specify meet their performance expectations. Pro-Twist takes that responsibility seriously, and we have the data to prove it. Our two-step testing process ensures that you can expect the best when you open a box of our fasteners.

Choose Pro-Twist for your next commercial or residential project by contacting your local dealer or one of our product specialists.

Pro-Twist. Driven by quality and chosen by professionals. Every box, every screw, every time.