| Factors that determine the selection of a fastener | |||

|---|---|---|---|

| Application | Point Design | Body Diameter | Length |

| Head Style | Drive Type | Material | Thread Type |

| Finish or Plating | Code Approvals | Quality Assurance | |

What are the materials being joined?

What is the total thickness of the material being joined?

When the application has been determined, it is then possible to choose a fastener with the appropriate point design, body diameter, length, head style, drive, thread type and plating requirements

Normally the body diameter required (or specified in your design print) is predetermined. If a diameter is not specified, refer to your supplier or manufacturer for recommendations.

Steel to Steel or composite to steel connections will require that you have three threads exposed. Any material to wood will be determined by the embedment requirement. Normally ¾” to 1” will be required. An example would be 1” material to 2 x 4 requiring ¾” embedment would mean your fastener should be a minimum of 1-3/4” long.

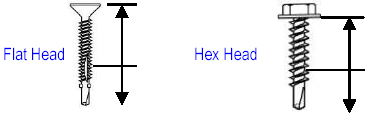

The length of a fastener is measured from the bearing surface of the fastener to the end of the point. For example, the flat or countersunk head is measured from the top of the head to the end of the point. A hex washer head is measured from under the head to the end of the point. The length of some self-drilling screws may require special consideration since some designs have an unthreaded pilot section or reamer wings between the threads and the drill point. These features may be necessary for the application and are considered in the overall length of the fastener, however the grip range of the drill screw will be different. It is still required that three threads be exposed for a good connection.

Common head styles include: bugle, flat, wafer, truss, modified truss, hex washer head, pan, round washer, trim, pancake and flat truss. Head styles are determined by the application, preference and availability.

Examples:

Drive types are usually determined by preference and availability.

Normally specified as Steel, Stainless Steel. Solid Bronze etc.

Common platings include the following:

In addition to these listed, there are many specialty platings given trade names by their respective manufacturer. Specifications should be required to show the corrosion resistance they specify.

Each manufacturer must comply with all codes and performance criteria to assure that the fastener supplied meets the required shear and tensile values. Proper codes and approvals must be available for inspection.

Carefully consider whether an on going quality assurance program is in place and maintained by your manufacturer/supplier. Head marking and independent testing are other key factors to consider before a screw is specified.

Copyright 2002, PrimeSource Building Products Inc.